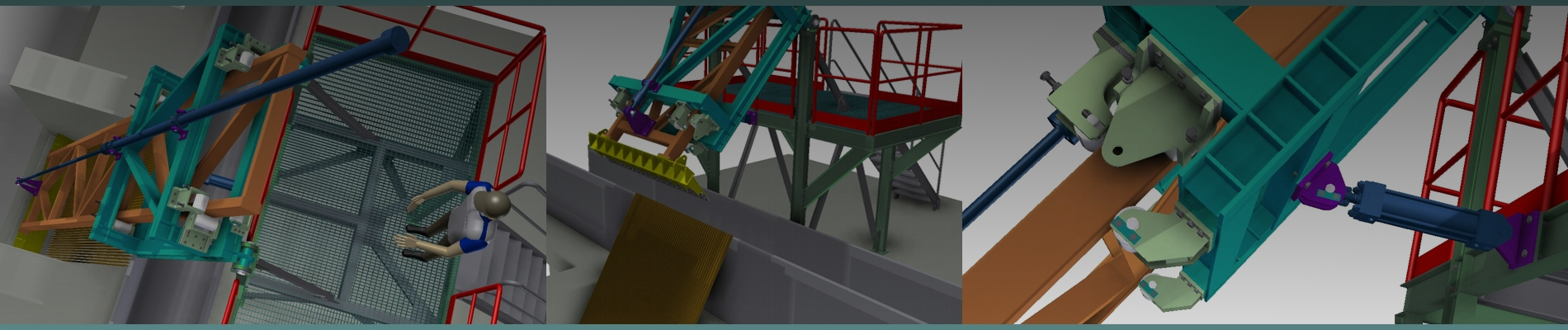

DA OLTRE 30 ANNI

AL VOSTRO SERVIZIO

società di servizi tecnici, siamo sempre stati partner fedeli

e affidabili dei nostri clienti.

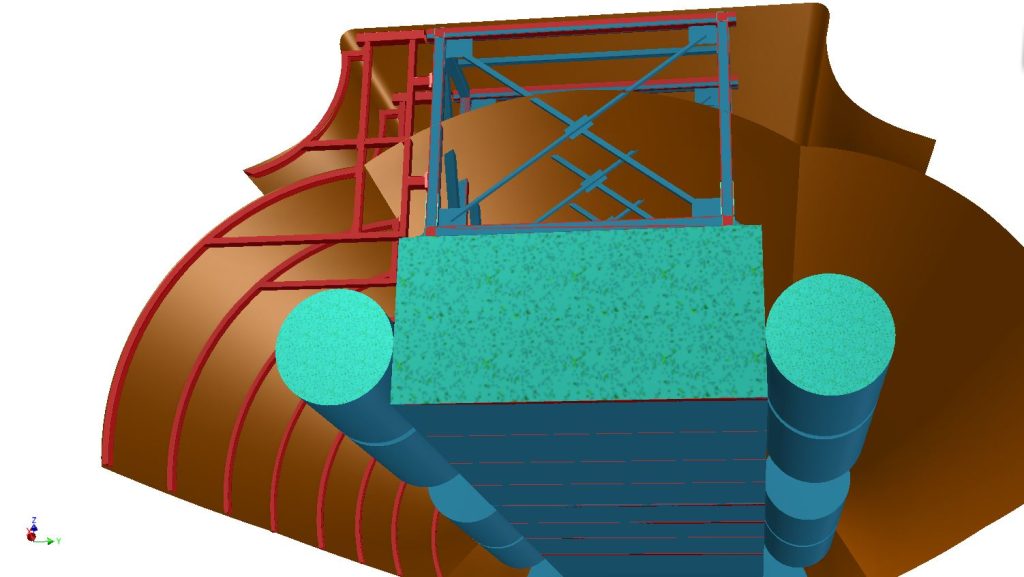

Abbiamo messo a frutto le sinergie delle diverse

competenze acquisite in anni di esercizio della professione da molteplici professionisti operanti in diversi settori dell’ingegneria meccanica, industriale, elettrica ed elettrostrumentale.