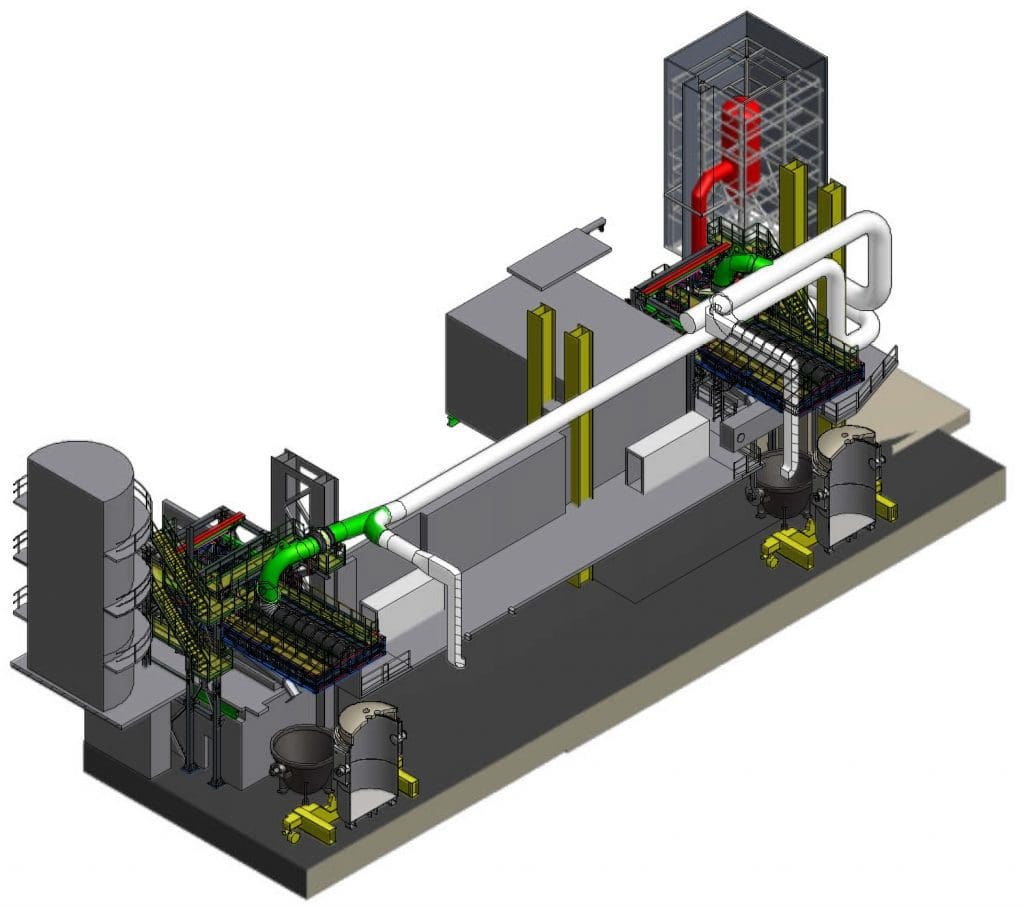

Structural design and specification of foundation loads for the new extraction hoods – Acciaieria Asea LF1 and LF2

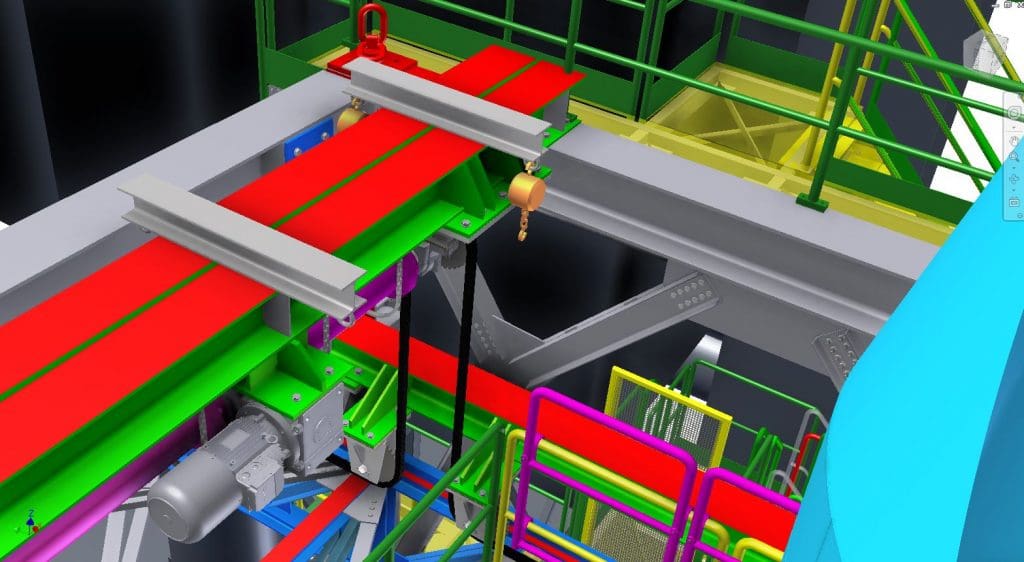

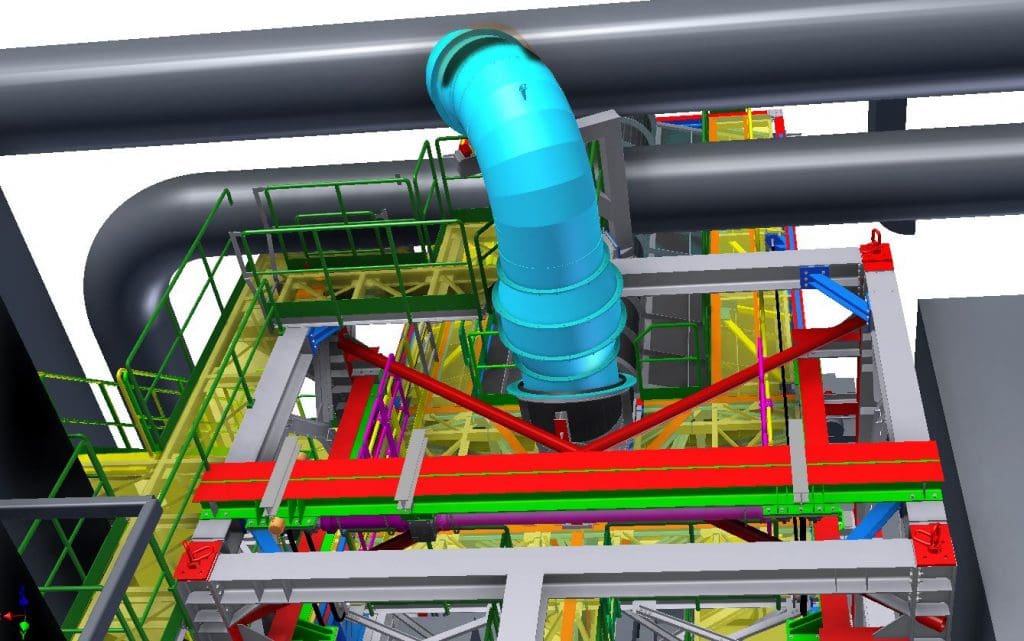

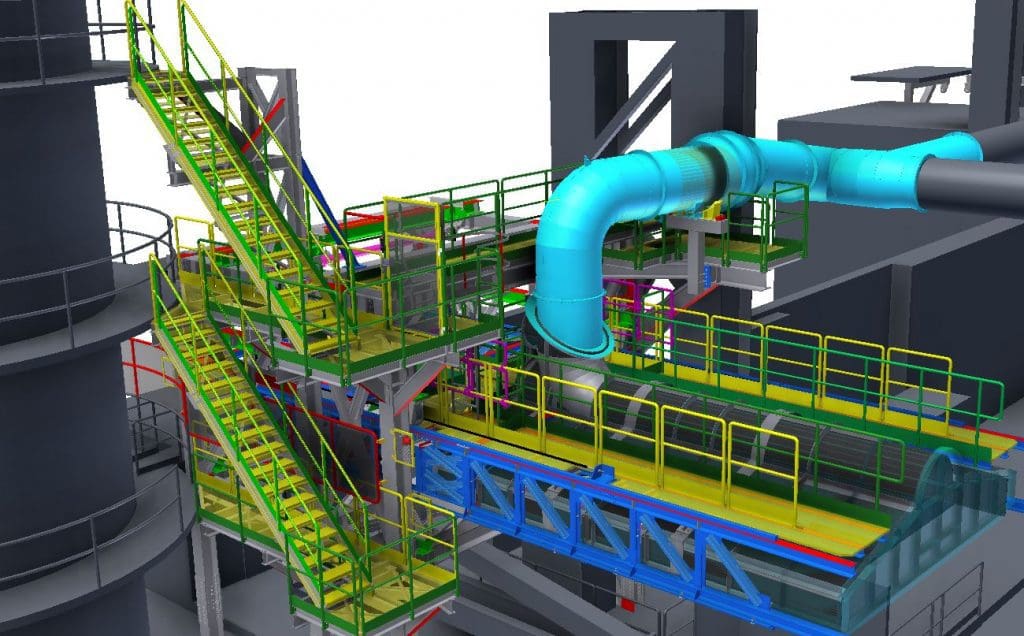

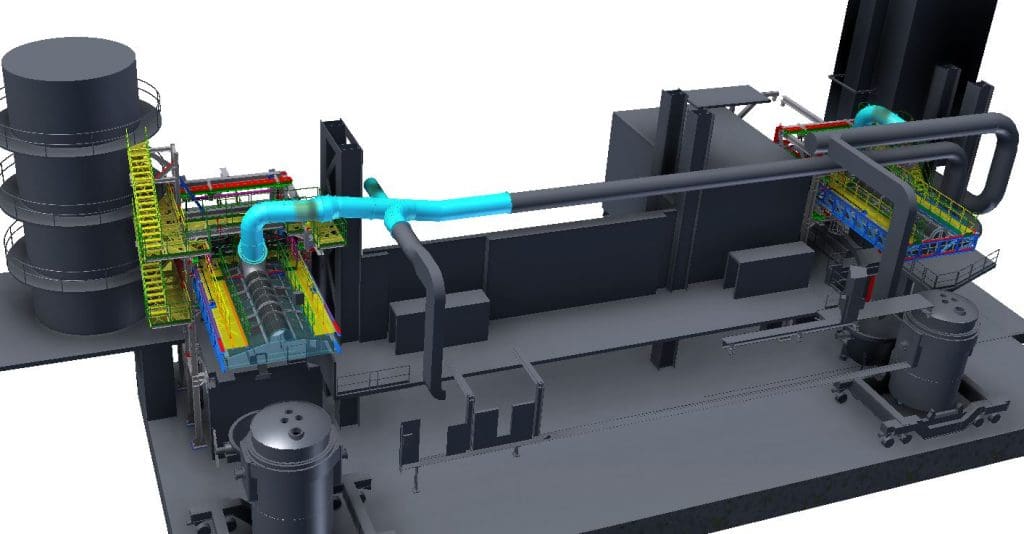

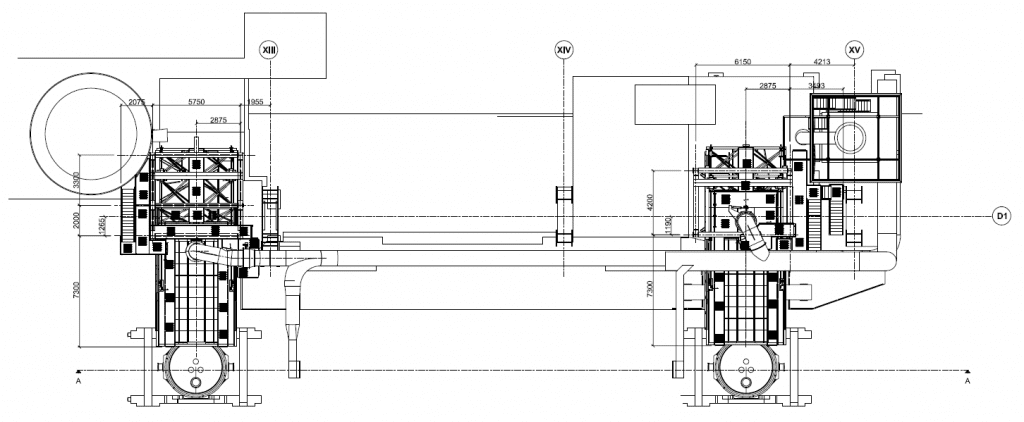

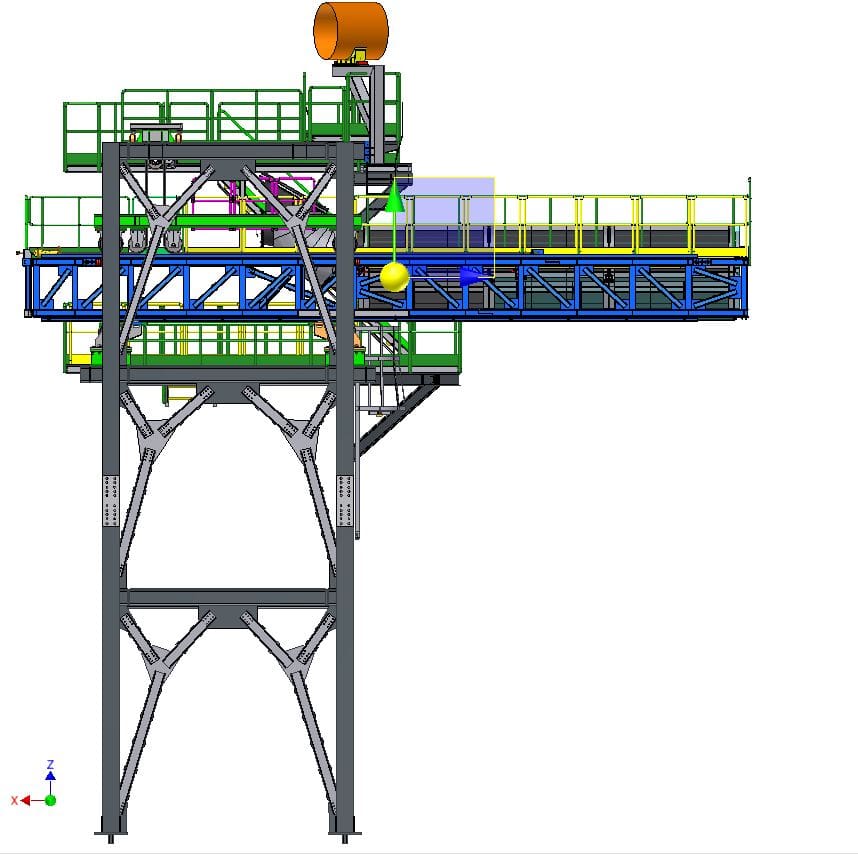

The system consists of two self-propelled fume extraction hoods running on two rails.

The project included position and coupling limit switches for the hood, a wire encoder to detect hood position, proximity sensors mounted on the gears to detect potential chain breakage, and electric interlocks on the access gates to the hood. The entire system is controlled by a PLC and can be operated from an operator touch-screen panel.

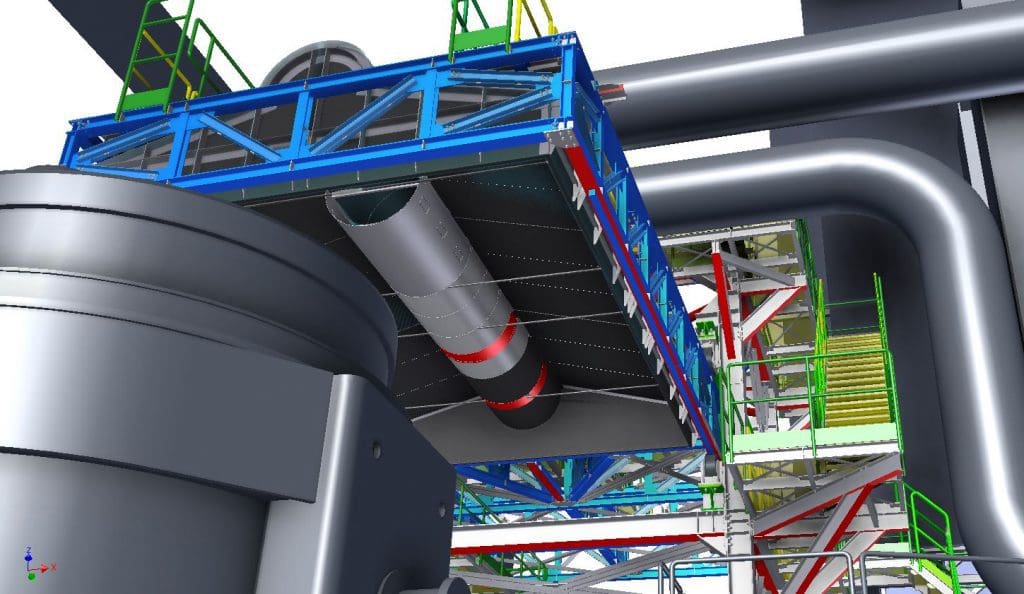

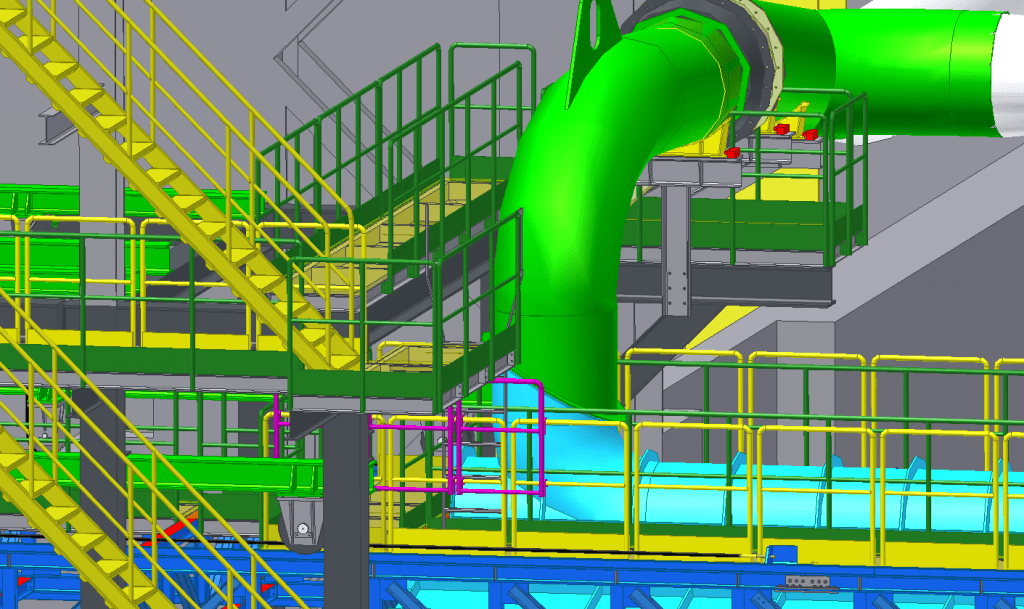

Technical services related to the detailed design of steel structures, hydraulic, electrical and civil works for the installation of the new mobile extraction hoods for slag removal on the LF1 and LF2 plants in the STEEL PRODUCTION department.

Verification of the newly designed structures and development of the modifications to be made to the existing structures to accommodate the new loads.