Skull melting plants – electrical, instrumentation, and automation design

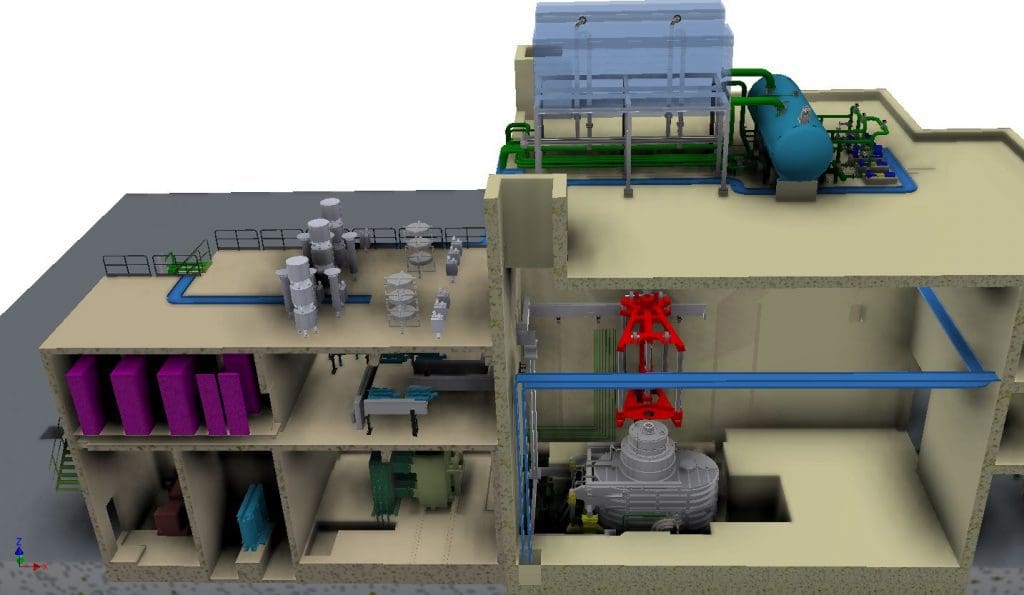

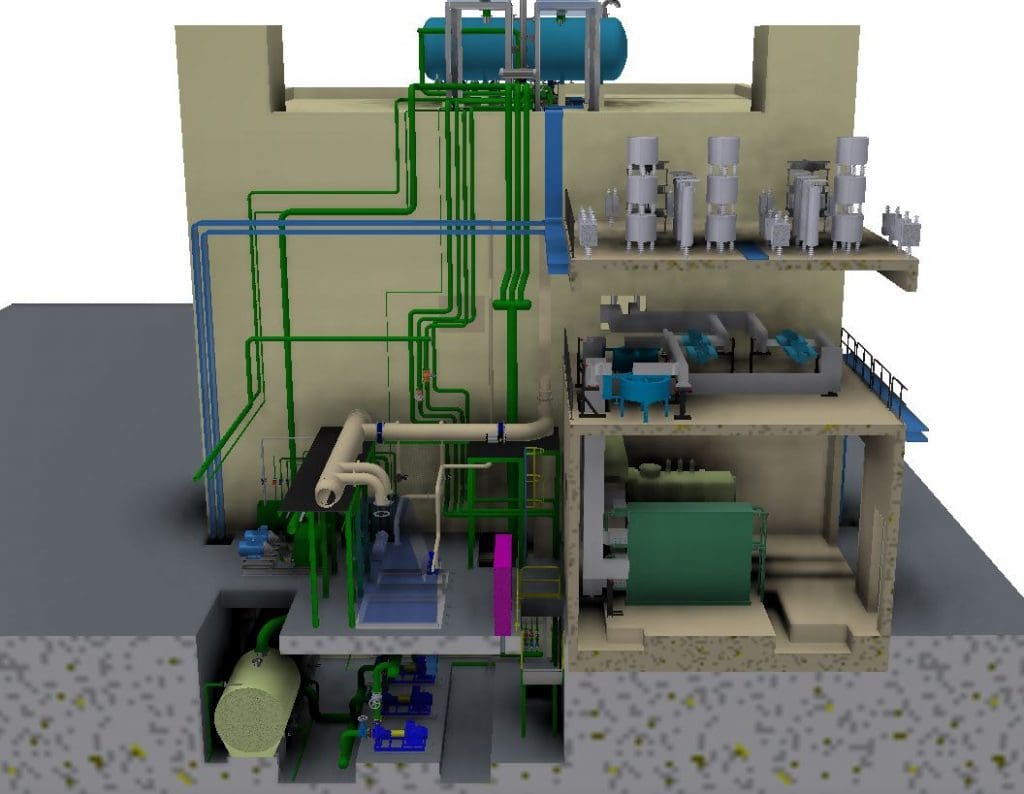

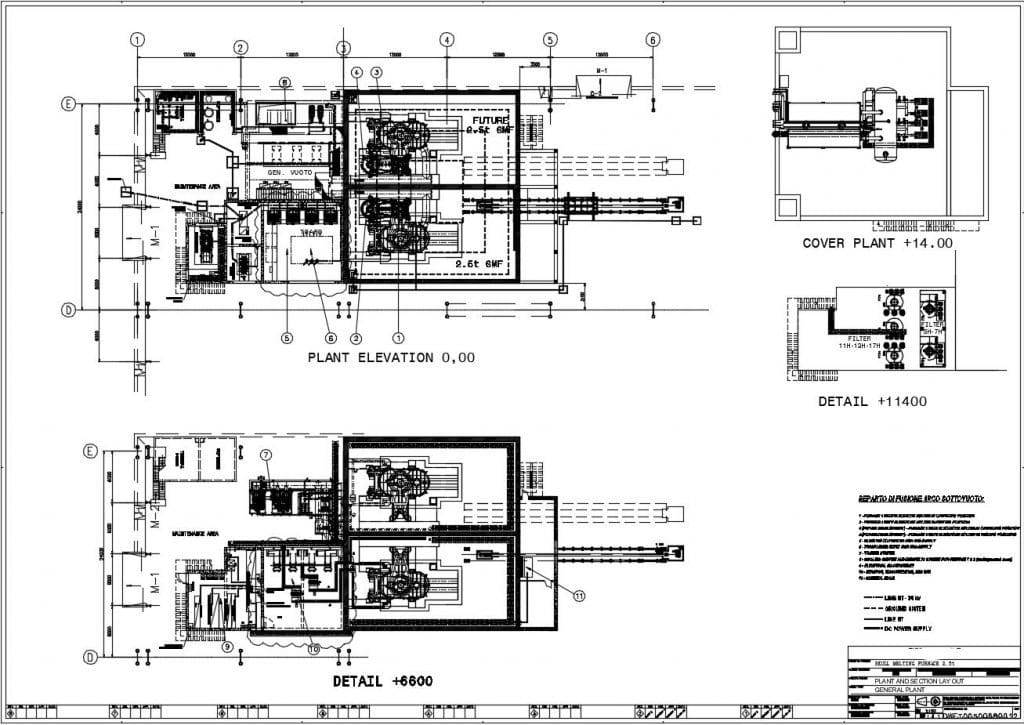

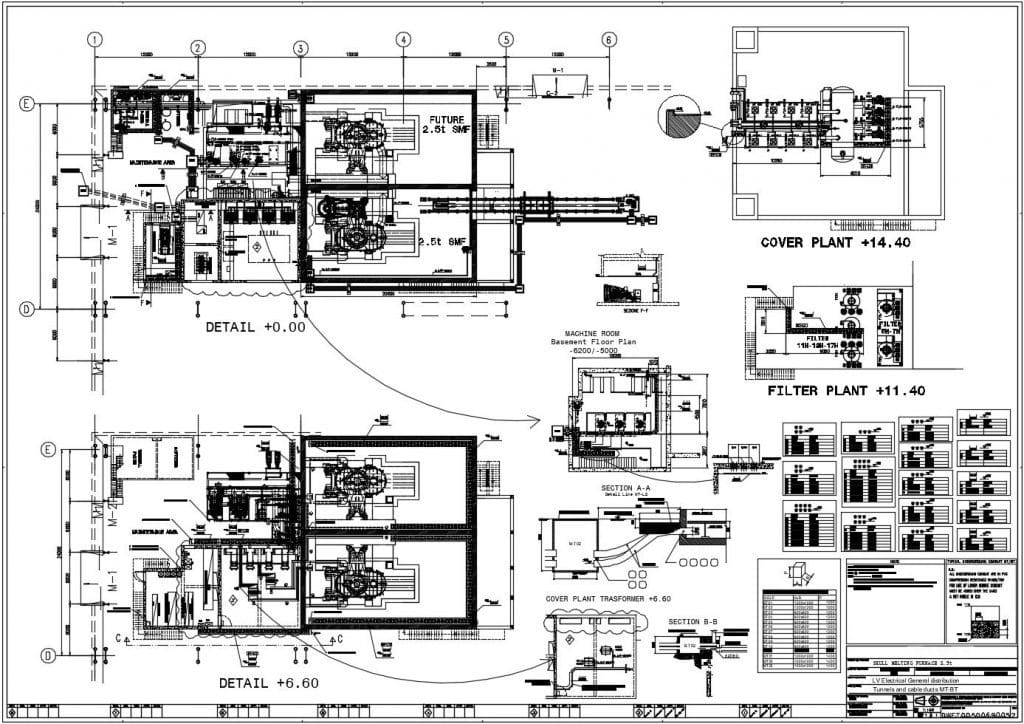

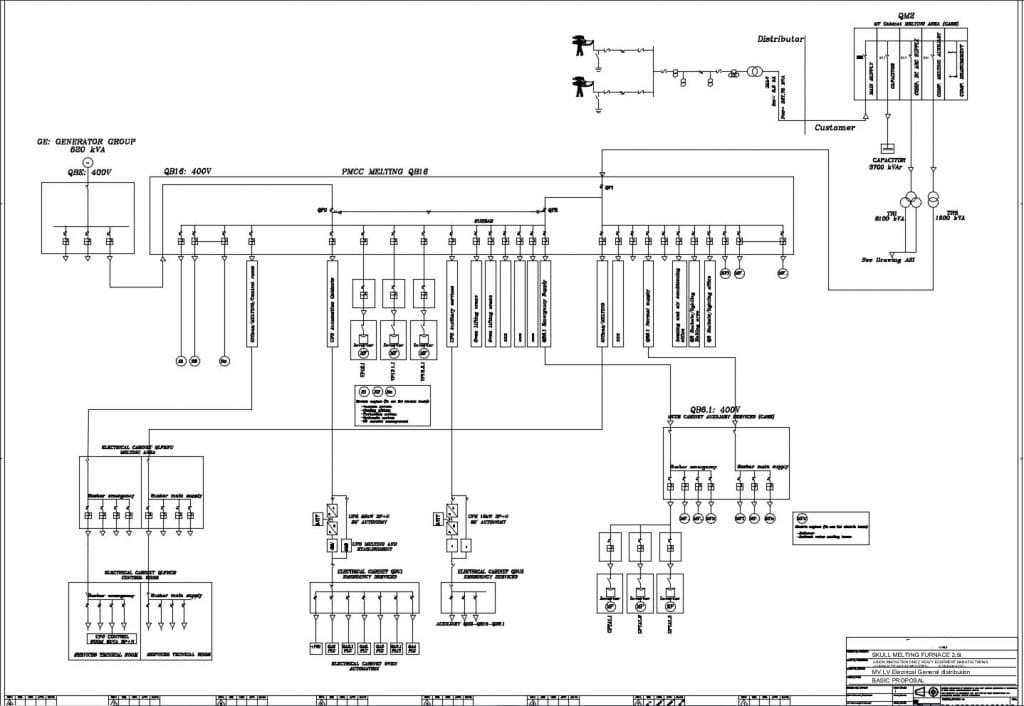

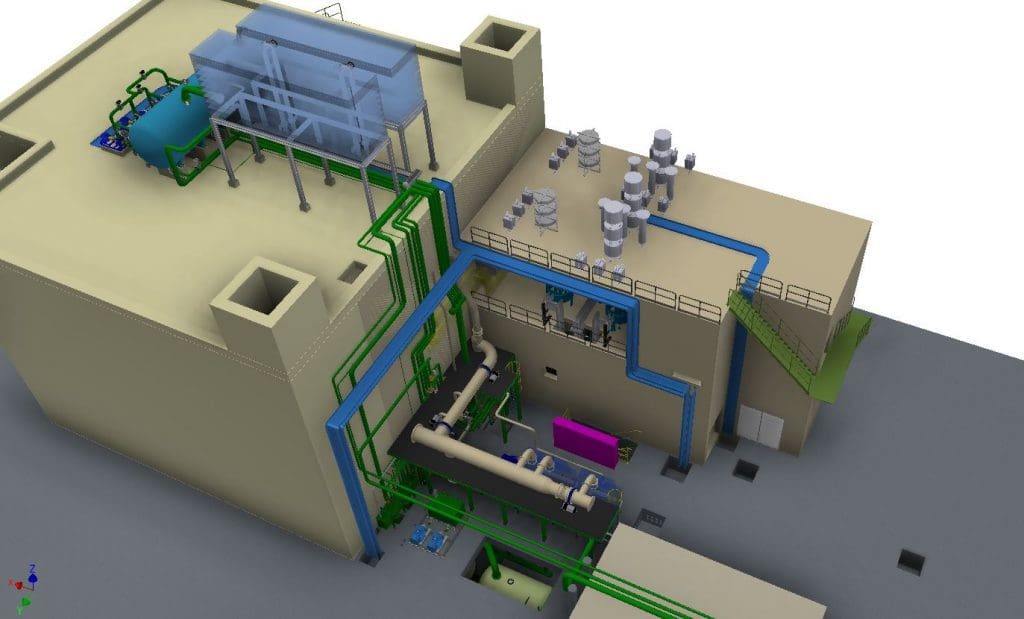

The plant, subject to dismantling and reassembly, consists of a set of equipment for the melting of scrap or sponge to produce titanium ingots. It is composed of a furnace based on Skull Melting technology and a VAR (Vacuum Arc Remelt) furnace.

The main purpose of the SKM 2.5 is to produce titanium ingots and alloys using:

- commercially pure (cp) titanium scrap and titanium alloys

- titanium sponge

- mixed charges of titanium scrap and sponge

- other alloying components

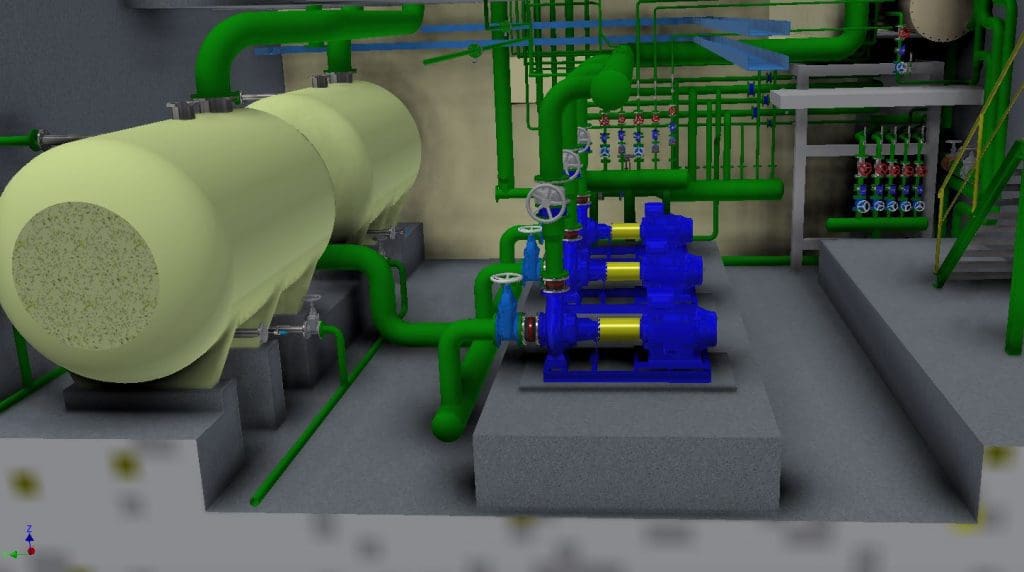

The plant is also suitable for melting other reactive metals (such as zirconium) and their alloys, as well as superalloys and nickel-based alloys (containing tungsten, manganese, cobalt, etc.). Melting takes place under vacuum inside a sealed steel vessel equipped with water-cooled walls.

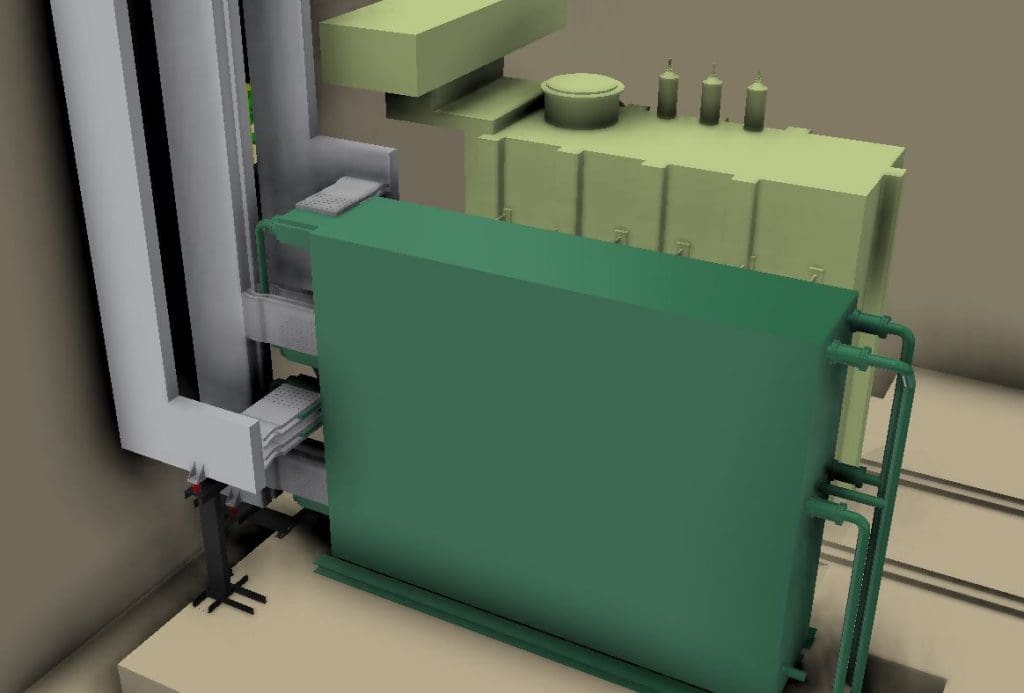

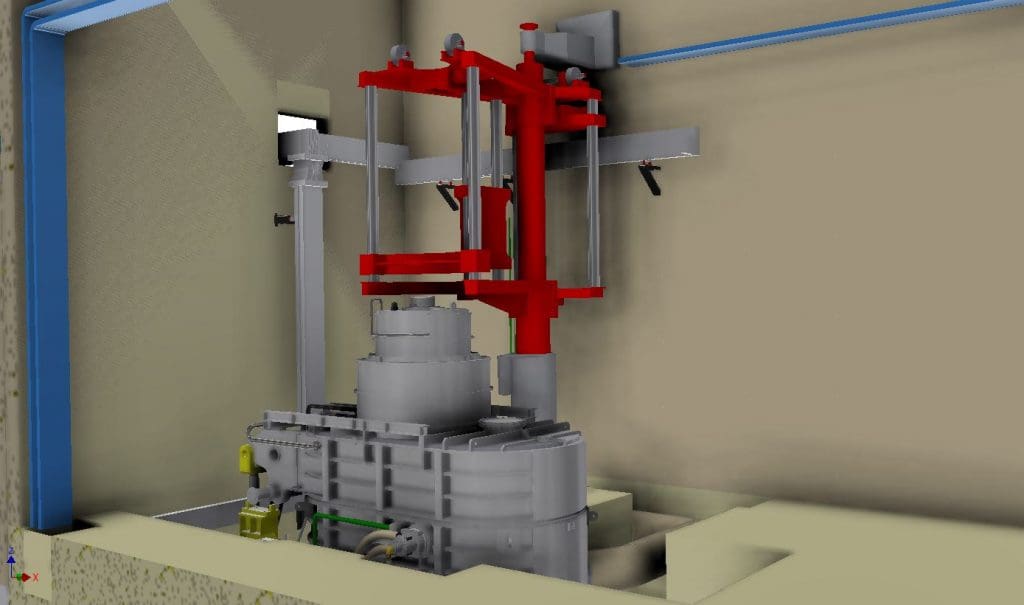

The electrode and the scrap charge to be melted are made of metals or metal alloys with the same composition. The copper crucible (water-cooled) has a parallelepiped shape and contains the entire melting charge. The consumable electrode is suspended above and aligned with the crucible by means of an electromechanical support device (RAM, or electrode arm, also water-cooled), which allows: DC power supply, mechanical support, and vertical movement.