Revamping of a grinding machine for slabs and billets

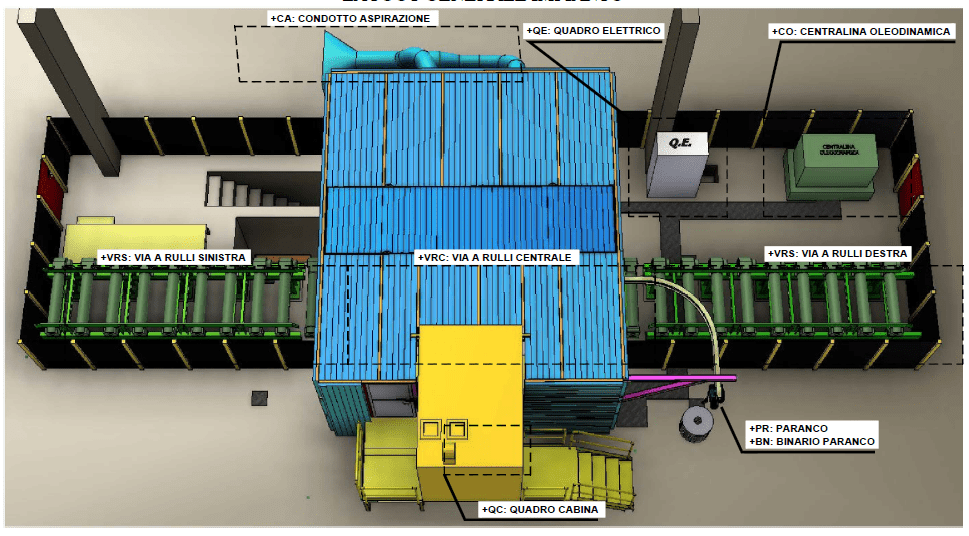

Revamping of a grinding machine for slabs and billets, consisting of the following mechanical units:

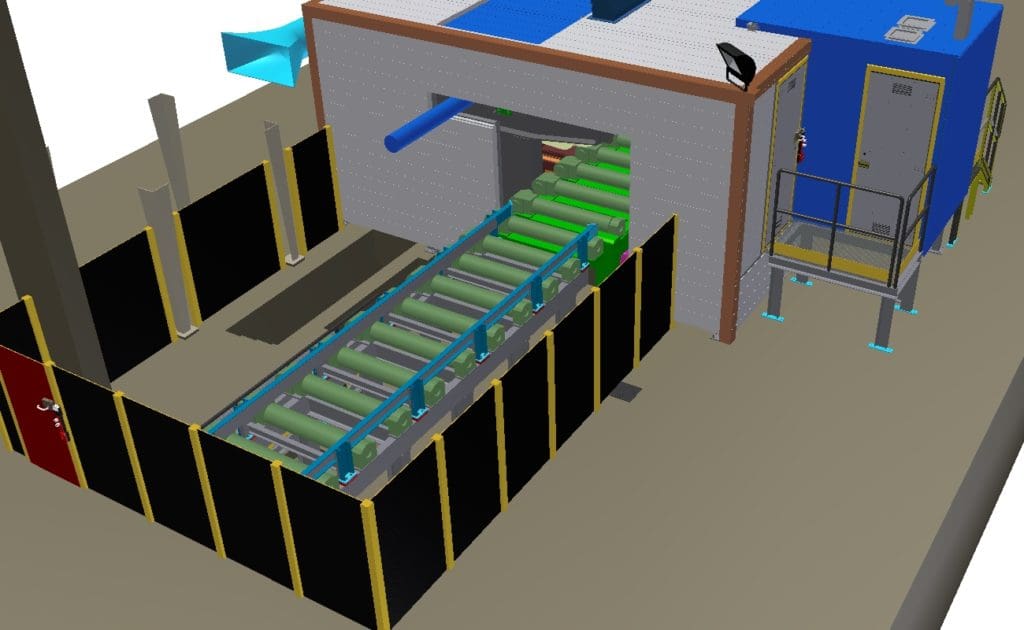

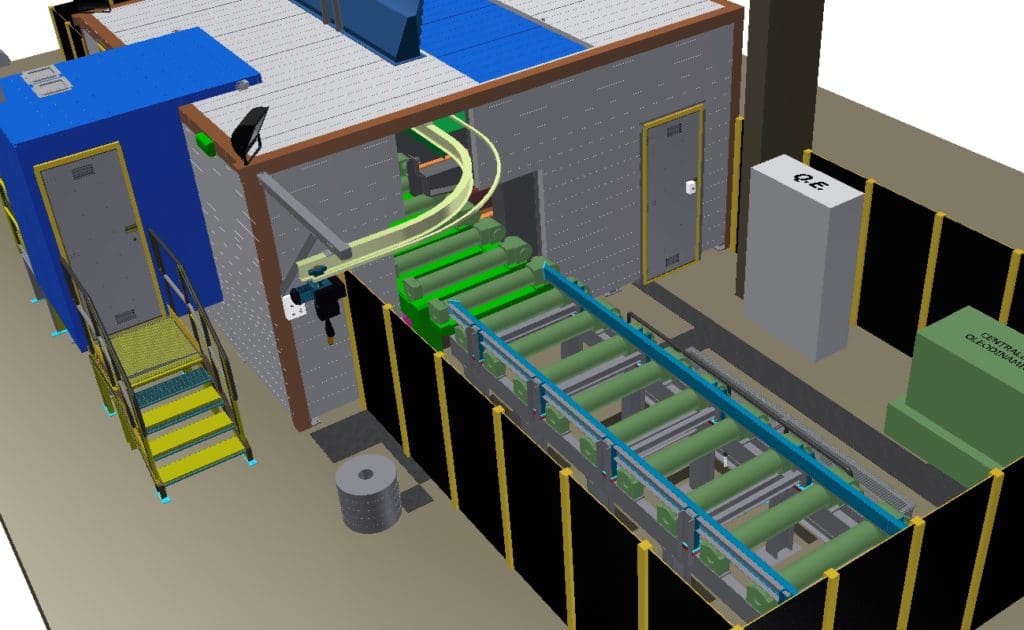

- Infeed roller conveyor

- Outfeed roller conveyor

- Roller conveyor in the grinding zone, including slab/billet tilting and clamping system

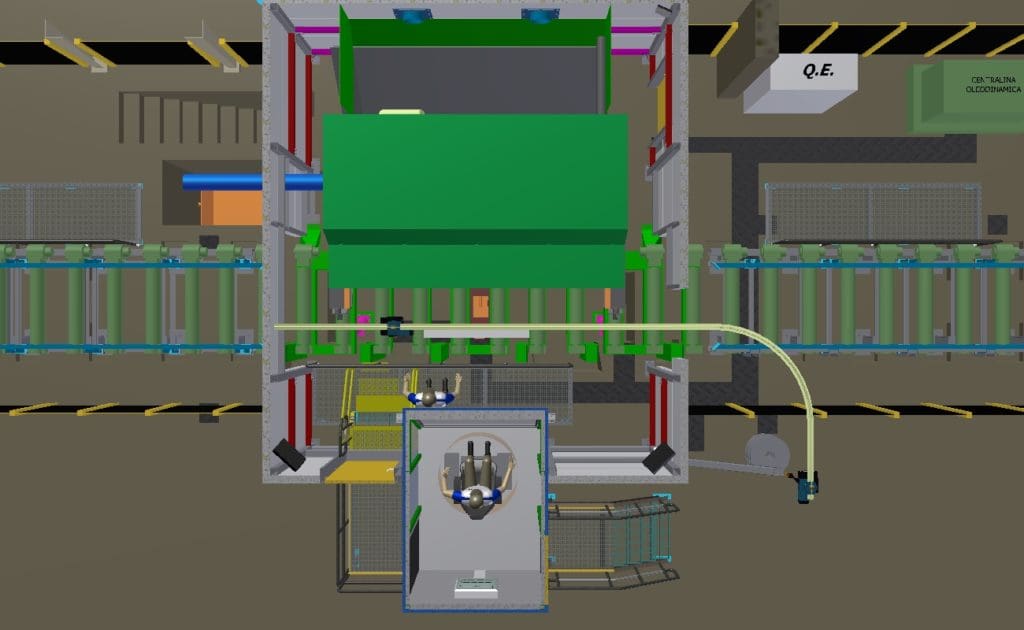

- Longitudinal and transverse movement carriage for the grinding wheel unit

- Grinding head, including wheel spindle and piston for wheel approach to the workpiece and grinding pressure adjustment

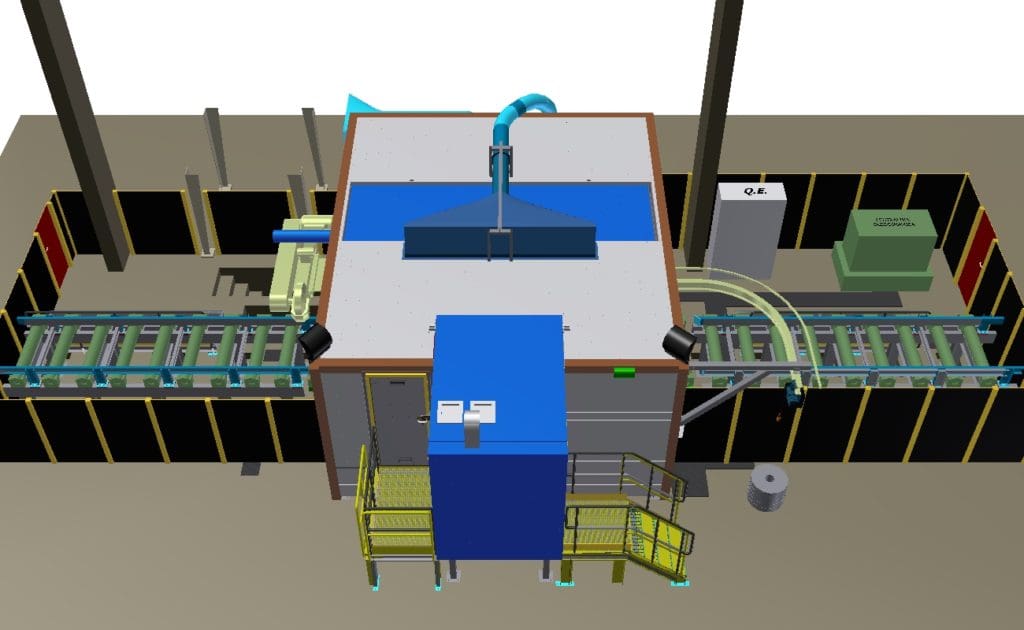

- Control cabin enclosure

- Extracted enclosure for the grinding area

Through the motorization of the roller conveyors, the workpiece is transported into the grinding area where the grinding unit is located. Grinding is performed by moving the grinding unit rather than the workpiece. To achieve this, the grinding unit is mounted on a wheel carriage that performs the longitudinal and transverse movements of the grinding wheel. These movements are hydraulically actuated by cylinders.

The approach of the grinding wheel to the workpiece is also actuated by a hydraulic cylinder.

The grinding pressure is regulated by a proportional pressure control valve powered by a dedicated electronic control board.

The central grinding table is equipped with a hydraulically operated tilting system and a hydraulic workpiece clamping system.

The grinding area is enclosed within a soundproofed enclosure with fume and dust extraction.

The extraction system consists of a bag filter and a centrifugal fan with chimney outlet.